Innovative Production Techniques: In-Mold Decorations Explained

Innovative Production Techniques: In-Mold Decorations Explained

Blog Article

Mastering In-Mold Decorations: Approaches, Patterns, and Ideal Practices for Optimal Outcomes

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of item design and manufacturing. In-Mold Decorations. By diving into the approaches, patterns, and finest techniques that underpin effective in-mold decoration processes, services can open a world of opportunities that not only boost the visual allure of their items but also simplify production efficiency and boost consumer interaction.

Material Selection

Material selection is an essential element of grasping in-mold decorations, as it directly impacts the high quality and resilience of the last item. When choosing products for in-mold decorations, it is necessary to consider factors such as compatibility with the molding process, the wanted visual outcome, and the environmental problems the product will certainly face. Thermoplastic products like polycarbonate, polypropylene, and abs are commonly utilized for in-mold decorations because of their flexibility and capability to accomplish intricate designs. These materials use outstanding moldability, enabling suppliers to create intricate shapes and patterns with accuracy.

In addition, the picked product should have good attachment properties to make certain that the design adheres securely to the substrate throughout the molding process. Attachment in between the product and the decor is vital for avoiding delamination and making certain resilient aesthetic charm. In addition, materials with high warmth resistance are liked for in-mold designs, specifically for items that will certainly be revealed to raised temperature levels throughout their lifecycle. By thoroughly picking the proper material for in-mold decors, producers can enhance the overall quality and longevity of their items, meeting the expectations of both end-users and clients.

Layout Technology

An essential element in advancing the field of in-mold decorations is the constant exploration and execution of design development methods. Style development plays a vital role in enhancing the aesthetic allure, functionality, and total quality of items produced making use of in-mold design procedures. By integrating ingenious layout components, producers can distinguish their products in the marketplace, attract customers, and stay in advance of competitors.

One of the crucial facets of layout technology in in-mold decors is the assimilation of elaborate patterns, appearances, and graphics that were previously testing to accomplish with typical decor approaches. Advanced technologies such as 3D printing and digital layout tools enable developers to produce complicated and thorough designs that can be effortlessly moved onto shaped parts. In addition, using dynamic colors, metallic surfaces, and unique results like gloss or matte appearances can even more elevate the visual appeal of in-mold enhanced items.

In addition, design development prolongs past aesthetics to include useful enhancements such as ergonomic forms, incorporated attributes, and personalized elements that accommodate particular individual requirements. By embracing design innovation, makers can open brand-new possibilities for item, creativity, and customization differentiation in the competitive landscape of in-mold decorations.

Manufacturing Effectiveness

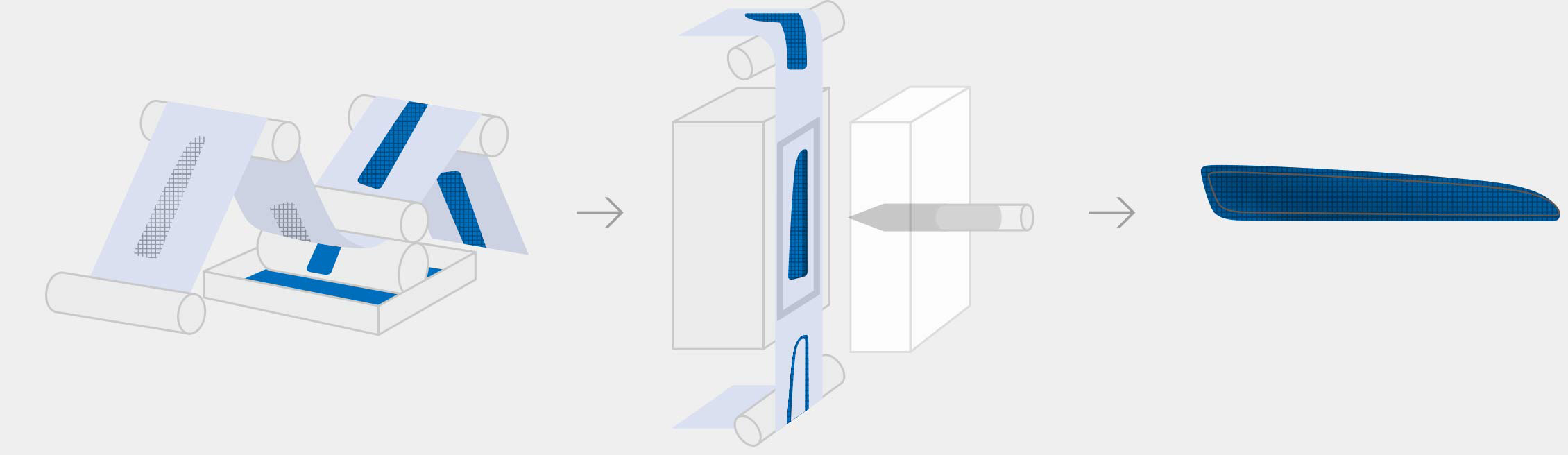

Effective manufacturing processes are necessary for converting the cutting-edge layouts developed in the area of in-mold decors into high-quality completed items that meet market demands and customer assumptions. In the world of in-mold decorations, manufacturing effectiveness includes different key facets that contribute to the total success of the manufacturing procedure.

Automation not only accelerates the manufacturing process but likewise enhances accuracy and repeatability, leading to an extra consistent and high-grade end item. Overall, an all natural technique to production efficiency is critical in maximizing the potential of in-mold decor methods and attaining ideal outcomes in the competitive market landscape.

Quality Assurance Steps

What are the key methods for ensuring rigid top quality control steps in the realm of in-mold decors? Quality control actions are vital in in-mold decoration processes to make sure the production of top quality and remarkable finished products.

Making use of sophisticated modern technologies such as computerized inspection systems can a fantastic read additionally enhance the quality assurance procedure by giving exact and reputable information for analysis. These systems can discover imperfections that may be missed by hand-operated inspections, consequently improving overall product high quality and uniformity.

Regular training and growth programs for employees involved in the in-mold decoration process can also add to preserving high-quality standards. By informing staff on ideal techniques, quality expectations, and the significance of attention to information, business can promote a culture of high quality awareness throughout the company.

Customer Charm

To improve the marketability of in-mold decor items, comprehending and providing to consumer choices play an important function in establishing their charm and success. Customer allure in in-mold designs is affected by various aspects, including style visual appeals, shade selections, durability, and overall performance. Consumers are increasingly looking for individualized and special items that reflect their individuality and style. As a result, supplying personalization choices such as tailored layouts, color variations, and textural aspects can substantially boost the allure of in-mold design products.

Final Thought

In-mold decorations offer a flexible and reliable way to improve product looks. By very carefully choosing products, embracing innovative designs, optimizing manufacturing procedures, applying quality assurance procedures, and focusing on customer charm, producers can attain optimal results. It is vital for business to constantly adapt and boost their approaches to stay affordable on the market. In-Mold Decorations. Understanding in-mold designs requires a holistic strategy that takes into consideration all aspects of the manufacturing procedure to ensure success.

In the realm of production, the art of in-mold decorations stands as a critical facet of product layout and manufacturing. Style innovation plays an important role in improving the visual allure, capability, and general high quality of items produced making use of in-mold decor processes.One of the key aspects of style technology in in-mold decorations is the combination of detailed patterns, textures, and graphics that were formerly challenging to accomplish with standard decor methods.Efficient manufacturing processes are vital for translating the cutting-edge layouts developed in the area of in-mold decorations right into premium finished items that fulfill market demands and customer assumptions. Providing personalization alternatives such as personalized layouts, shade variants, and textural components can significantly improve the allure of in-mold design items.

Report this page